Fiberglass and polythene chemical tank productions supply storage of chemicals with different concentration rates. Polythene acid tanks are produced as standard and dimensions cannot be changed. In addition, polythene acid tanks can be produced in certain volumes as silo type. It can provide resistance to all acids to be stored at ambient temperature in all concentrated ratios.

Polyester acid tanks are a solution partner for different sizes and details. It allows the stocking of acids at certain concentrations and at different temperatures. The polyester tanks that we produce by using 3 different resins provide resistance for acids in different concentrated ratios. Resistance tables:

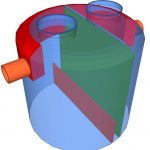

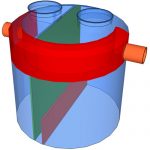

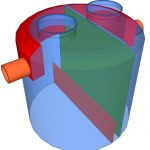

Polyester Chemical Tank Productions

They are chemical storage tanks that can be produced as horizontal, vertical, silo and mixer on demand. You can examine the tank samples that we have completed the production of.

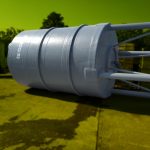

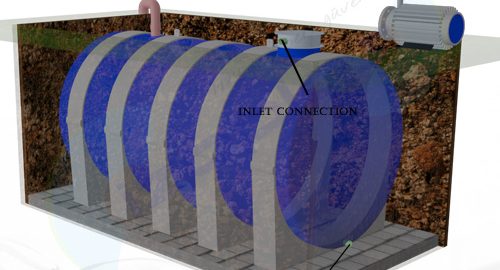

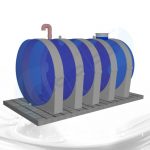

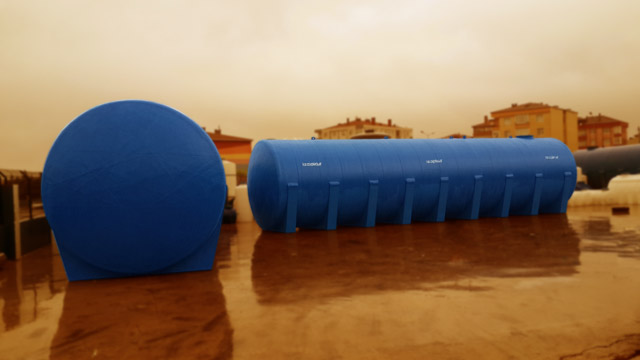

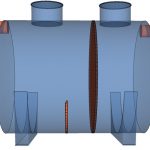

50 Ton Horizontal Chemical Tank

The 50 tons polyester horizontal acid tank we produce for sodium sulfate storage has been designed in line with the demand from the company. Manufacturing has been completed with using vinylester epoxy resin.

| Diameter | 310 cm |

| Height | 325 cm |

| Length | 680 cm |

| Manhole | 70 cm |

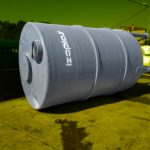

50m3 Vinylester Silo Chemical Tank

The silo tank we have specially produced for betaine stocking also includes a special stand. All outlets on the product designed by us according to usage details are PVC material.

| Diameter | 310 cm |

| Height | 710 cm |

| Platform Height | 190 cm |

| Manhole | 70 cm |

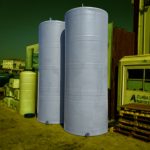

15m3 Vinylester Silo Chemical Tank

It is specially produced for betaine stocking. There is a special level indicator on the product.

| Diameter | 180 cm |

| Height | 557 cm |

| Platform Height | 50 cm |

| Manhole | 46.2 cm |

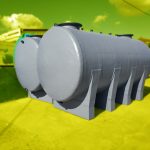

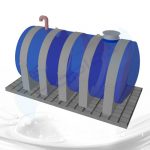

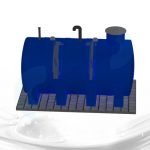

25m3 Vinylester Horizontal Chemical Tank

The chemical tank we have produced for the storage of the ferric chloride is the standard product of ours. The special PVC removable level indicator is located on the product.

| Diameter | 250 cm |

| Height | 270 cm |

| Length | 510 cm |

| Manhole | 70 cm |

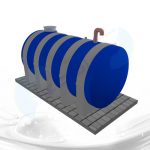

500 Liter Vinylester Horizontal Chemical Tank

The products we have produced for hydrochloric acid storage are used for transportation purposes. With special anchor system, you can fix the products.

| Diameter | 80 cm |

| Height | 100 cm |

| Length | 100 cm |

| Manhole | 12 cm |

Polythene Chemical Tank Productions

Polythene acid tanks, which we produce in different thicknesses according to chemical concentration ratios, are produced in standard sizes and have 1 inlet manhole and 1 polyethylene external threaded outlet fitting. Products can be supported with sheet metal belts upon request. It is not suitable for use except at ambient temperature.

20m3 Polythene Chemical Tank

The product we have produced for caustic acid storage has been thickened by 60%. Thus, the product has been made durable for 48% caustic acid storage. All other equipment is made of PVC and has been placed in accordance with the company’s project.

| Diameter | 282 cm |

| Height | 343 cm |

| Level Indicator | 1″ PVC |

| Manhole | 45 cm |

| Inlet | 1″ PVC |

| Outlet | 1,5″ PVC Valve |

15m3 Polythene Chemical Tank

The polyethylene acid tank, which is produced for storage of diesel, has one manhole and also one external threaded union made of brass material as standard. Upon request, 2 sheet belt reinforcements were provided.

| Diameter | 282 cm |

| Height | 282 cm |

| Manhole | 45 cm |

| Outlet | 2″ Out Threaded |

5m3 Polythene Chemical Tank

The product we have produced for stocking 98% sulfuric acid is 100% thickened compared to the standard water tank product. It has 1 PVC Flange for inlet, 1 PVC flange for outlet and 1 PVC flange for overflow.

| Diameter | 180 cm |

| Height | 220 cm |

| Manhole | 40 cm |

| Outlet | 2″ PVC Flange |

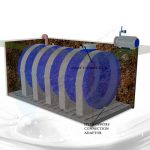

17m3 Polythene Silo Tank

Standard polythene silo tank with open top is suitable to mixer placement. Tank has a metal platform and a metal ladder. Outlet is polythene outside threaded.

| Diameter | 282 cm |

| Height | 368 cm |

| Connical Height | 48 cm |

| Platform Height | 50 cm |

| Outlet | 2″ PVC Flange |