Ingredients

Underground water tanks are produced as fiberglass and resisted to pressure. Fiberglass underground water tanks have dividing walls inside of it and support tanks against to load that will come on it.

Underground Water Tanks

Production can be supplied up to 100 cbm. Also we can design tanks accordingly different pump types.

Specifications

- Production is fiberglass.

- For all capacities we can supply production up to 100 m3.

- Sizes are changable accordingly project.

- Production can be supplied as vertical cylindrical, horizontal cylindrical and cubic.

- Our production is supplied accordingly EN 976-1 standarts.

- All tests are made in our own laboratory.

- Fiberglass tanks are stainless and noncorrosive.

Dimensions and Details

If you need any further information or question, please don’t hesitate to contact with us. All standard tanks are produced accordingly 30 cm elavation level. For more elevation level you should inform us. Tank design will be changed accordingly your request. Also inlet, outlet and all other equipments needs, please infom us about that.

Different Use Types

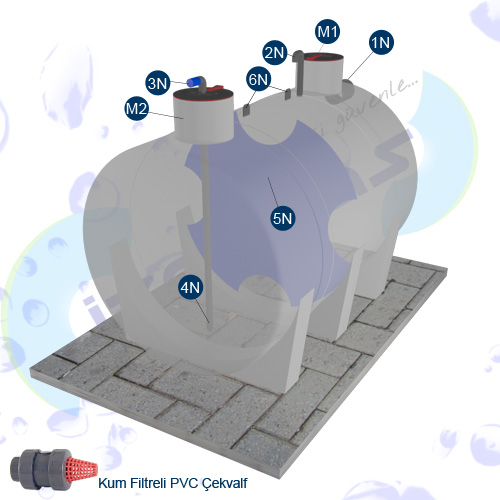

Rainwater Collection Tank

Other options show variety for pump types. You can use hydrophores or submersible pump. We can design your tank with appropriate equipments accordingly pump type that you will use.

| M1 | Inlet Chamber Access Cover |

| To supply access to inlet chamber. | |

| M2 | Pump Chamber Access |

| To supply access to inlet chamber. | |

| 1N | Rainwater collection pipe. |

| Pipe size and position on tank can be changed also quantity of it can be increased to collect rainwater from different connection lines. | |

| 2N | Ventilation Pipe. |

| PVC pipe with double elbow. Supply ventilation to water. | |

| 3N | Pump Connection Pipe |

| Connection pipe will be used collected water serve with hydrophore. We can supply more than one connection equipment. For example, one connection can be used garden irrigration sytem and one connection for your home. | |

| 4N | Foot Checkvalve |

| Will be assembled to bottom side of pump pipe to prevent any material damages hydrophore. It shall be cleaned at regular intervals. | |

| 5N | Dividing Wall |

| Support tank against to soil pressure. | |

| 6N | Lifting Lugs |

| Using for placement of tank to underground. | |

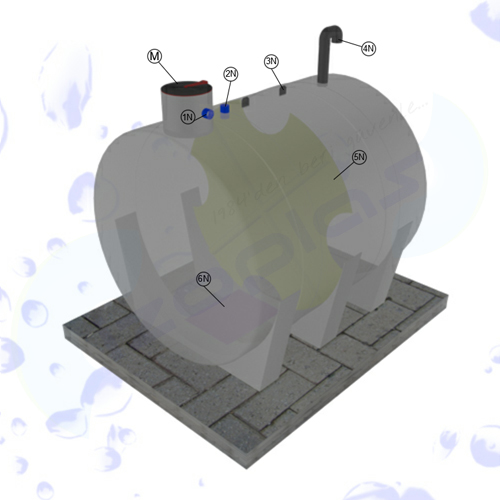

Submersible Pump Use

| M | Access Manhole |

| Use to install of submersible pump. | |

| 1N | Inlet Connection |

| It is a inside threaded connector. You can connect your inlet line to this equipment for water fill. | |

| 2N | Pump Connection |

| It is a doubleside connector and inside threaded equipment. Pump connection will be completed with these equipment. | |

| 3N | Lifting Lugs |

| Using for placement of tank to underground. | |

| 4N | Vent Pipe |

| Use to ventilation of water. | |

| 5N | Dividing Wall |

| Support tank against to soil pressure. | |

| 6N | Pump Table |

| Submersible pump will be installed onto this table. Because of tank’s cylindrical shape, table will be useful during installing of submersible pump. | |

Underground water tanks can be produced for hydrophore pump. You can contact with us for more details. Also we can produce separator undergorund water tanks. You can visit separator tanks for more details.

Underground water tanks are installed and buried accordingly drawings. All details are clarified on drawing.

Excavation sizes are clarified on drawing. Don’t make excavation except this.

Burial depth is 30 cm as standard. You should inform us if burial depth is more than 30 cm.

Don’t use excavation soil to bury tank.

You should use pine gravel (3/8″) or thin sand has a specific weight 1600 kg/m3.

Take precaution in areas with excess of rain.

Please provide information in areas with wehicle passage.

You can view guiedline for more information.

| Container Shipping | Maximum Tank width is 230 cm |

| Standard Trucks | Maximum Tank width is 250 cm. |

| Flatbed Trucks | Tank is wider than 250 cm |

All Rights Reserved | ATILIMSAN GRUP A.S.