We are pleased to announce Enerau & Izoplas partnership for wastewater treatment tanks and system in North America & Canada. We will supply and install the best land development and indsutrial systems according to your requirements. Also you can access all izoplas tanks from North America, Canada & Europe through ENEREAU.

Izoplas’ uncorrosive and durable fiberglass and polyethylene tanks are equipped with Enereau’ latest technology and membrane filtration systems. Combined, our technology will produce the highest quality of reuse water.

Wastewater Treatment Tanks & System

The nrPUR™ membrane platform is a low-energy, self-cleaning ultrafiltration (UF) system for the treatment of low-to high- strength wastewater to high-quality discharge or reuse standards. The technology is highly flexible and suitable for both domestic and industrial wastewater, from a wide range of applications that include hotels & resorts, small communities, craft breweries, wineries, dairy and other wastewater. Configured around a series of modular process building blocks, nrPUR™ easily integrates into advanced biological treatment systems (i.e. Membrane Bioreactor (MBR), MBBR, MABR, etc) to provide effective TSS & BOD5 reduction of >95% on wastewater streams from 300mg/L to 10.000 mg/L, producing safe, reuse-quality water. When combined with our advanced polishing technologies the nrPUR™ system can treat trace micro pollutants (e.g. phosphorus, ammonia, etc) to safe discharge levels.

The nrPUR™ UF membrane racks are submerged in the water to be treated and connected to the permeate extraction system. All suspended solids and micro-organisms larger than the membrane pore size, typically less than 0.1 µm in size, will be rejected by the membranes and only clean, solids-free water will be dischargedas permeate. The permeate can then be discharged, or sent for reuse or further polishing steps.

On a continuous basis, air is bubbled from a grid of diffusers installed at the base of the nrPUR™ racks, acting as a scouring mechanism to reduce the potential for biofouling on the surface of the membrane and to enhance the mixing of the biomass within membrane tank.

A fully automated system, the nrPUR™ platform is designed to provide many years of reliable, effective and affordable treatment of water and wastewater.

Wastewater Treatment Process

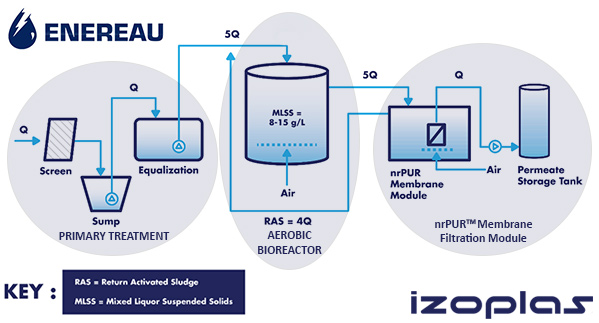

Wastewater is centrally collected and pretrated to remove non-biodegradable solids and transferred to an equalization tank, where variations in flow and concentration are moderated. The balanced wastewater is transffered under level control to the system’s BioReactor. Wastewater is recirculated between the BioReactor and the membrane tank at a rate of 4-5 times average daily flow.

The bioreactor is a continuously-stirred, complete-mix reactor designed to ensure effective biological digestion of the organic materials in the secondary aeration step of the activated sludge process. The appropriate BioReactor volume is dictated by the F/M ratio and the mass loading of BOD per cubic volume of reactor.

The activated sludge process converts the soluble organic material present in the wastewater into CO2, H2O and biological cell mass. An aeration system provides the oxygen required for this process. The mass of oxygen transferred is based upon the design daily influent BOD load.

The liquid phase of the mixed liquor is pulled through the membrane at a predetermined rate, or flux, established for each specific application. The mixed liquor suspended solids (MLSS) are rejected and moved away from the membrane by the air scour and hydraulic action. Permeate is drawn through the membranes under suction by permeate pumps and discharged to a clean water storage tank or for further polishing.

Typical Sytem Results:

- BOD: <5 mg/L

- TSS: <5 mg/L

Advantages

- Low Energy / Opex

- Fast Reduction of TSS, COD / BOD and micro pollutant levels

- Simple & Easy Use

- Compact / Small Footprint

Wastewater Treatment Tanks

Other Products

You can also purchase all izoplas tanks through Enereau from Canada & North America & Europe. With the business partnership of Izoplas & Enereau you can order easily all products of Izoplas.

Fiberglass (Poliester) Water Tanks

We can produce fiberglass water tanks from 1000 liter up to 100.000 liter. Tanks can be produced both of horizontal and vertical. Also we can produce tank with alternative sizes according your requests and shipping types, allowing us to optimize designs to reduce shipping costs for all countries.

To see all productions for fiberglass water tanks you can visit page. Poliester Water Tanks

Advantages

- Non-corrosive

- Long Useful Life

- Much more alternative sizes.

- Up to 100 cbm production capacity.

- Vertical & Horizontal & Rectangular Options

- Different inlet and outlet options.

- Material and Resistance Tests.

Underground Water Tanks

Underground (buried) tanks are produced as fiberglass and can be produced up to 100 cbm capacity. Tanks can be designed according to different pump use. Also, you can use underground water tanks for collection of rainwater.

To see all productions for fiberglass underground water tanks you can visit page. Underground Water Tanks

We can produce underground water tanks with internal pump chamber so that you can install your pump inside of tank.

Polyethylene (Plastic) Water Tanks

Polyethylene water tanks are produced from 100 liter to 5000 liter as horizontal and from 50 liter to 25000 liter as vertical. Tank sizes are standard and can not be changed. We can supply different inlet and outlet options for you. But manway size is standard.

Polyethylene tanks are also used as chemical storage tank. We increase thickness of tank according chemical concentration rate. Polyethylene tanks are used as chemical storage tank only with ambient temperature. To get more information Polyethylene Water Tanks

Advantages

- Non-corrosive

- Lower Prices

- Food-Grade

- Lightweight

- Easy shipping

Projects

Enereau’ best & latest technology nrPUR™ treatment system & izoplas’ fiberglass tanks continue to install in different countries.

BVI PROJECT

Norwich, UK

USA

Tortola British Virgin Islands

Contact

To get more details, for your orders from Canada & North America and to get more information about treatment system you can contact with Enereau:

- sales@enereau.com

- +1 (905) 993-1761

- 19 Driftwood Trail Ridgeway, Ontario

All Rights Reserved | ATILIMSAN GRUP A.S.